Extrusions

Precision-engineered to meet your exact needs.

Metra North America is no stranger to delivering high-performance solutions for the most demanding applications. With advanced manufacturing, deep expertise and a commitment to quality, we create extrusions that combine strength, efficiency and innovation.

Stock & Open Dies/Dunnage

What You Need. When You Need It.

We inventory a wide range of stock dies and open profiles, enabling us to expedite production and reduce lead times. We also offer custom die services for unique profile requirements.

To ensure safe handling and transportation, we provide tailored dunnage solutions to protect profile integrity.

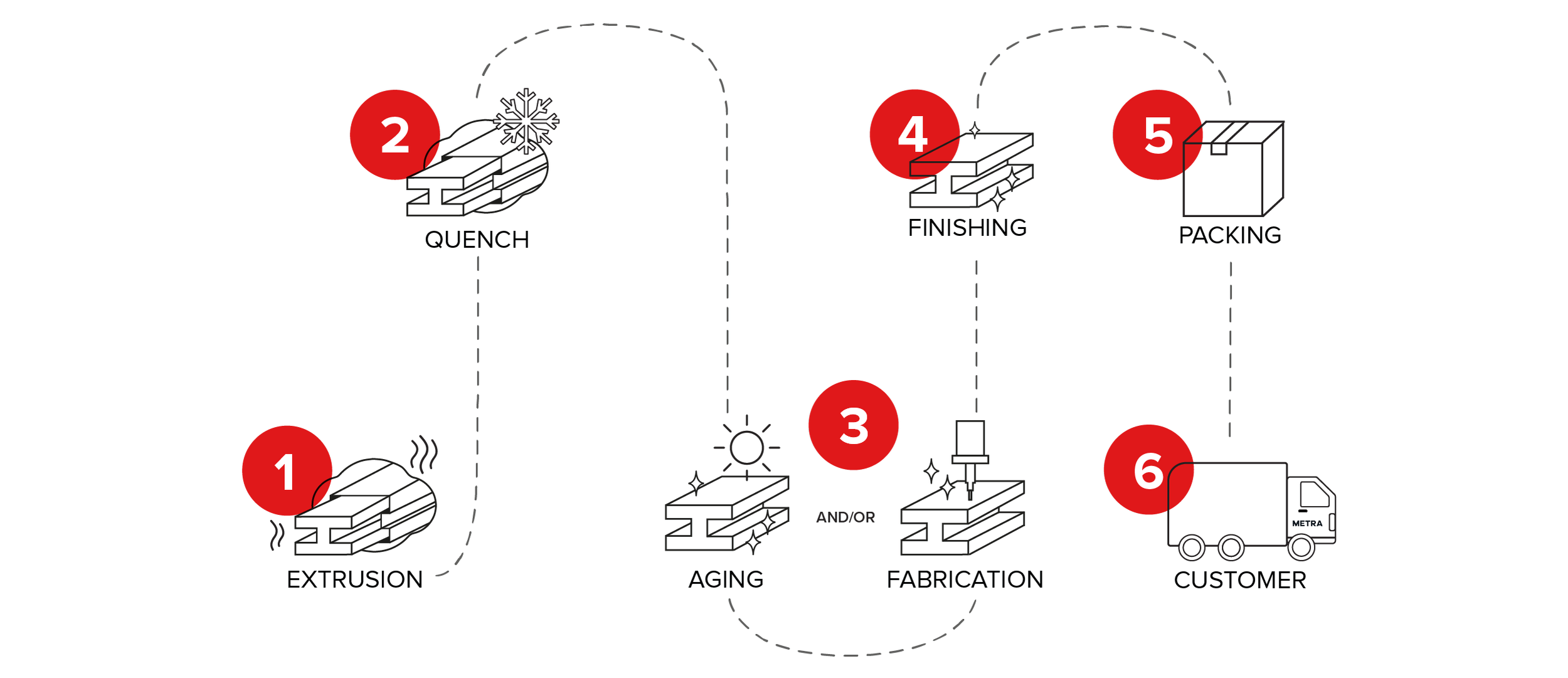

Process Flow

Quality And Precision At Every Step

Our aluminum extrusion process begins with selecting the appropriate alloy and die design. Preheated aluminum billets are then forced through the die under high pressure, forming the desired profile.

Post-extrusion, profiles undergo quenching, mechanical treatment, and aging to attain specified metallurgical properties. Depending on your requirements, extrusions may receive additional finishing, fabrication, or assembly before packaging and shipment.

Alloys & Tempers

Renowned For Strength and Finish

We specialize in 6000 series heat-treatable aluminum alloys, renowned for their strength, machinability, corrosion resistance and excellent finish quality. Post-extrusion, the aluminum is aged in temperature-controlled ovens to achieve the precise mechanical properties required. Commercially pure aluminum grades are valued for electrical conductivity and formability, not structural strength.

See the list below for specific alloys.

1050, 1100, 6005, 6005A, 6061, 6063, 6082, 6463, E6063

Value Added Services

Enhancing Beauty and Functionality

To enhance functionality and aesthetics, we offer a range of value-added services, including precision cutting and fabrication, deburring, bending, CNC machining and buffing.

It’s an integrated approach that ensures high quality, ready-to-use aluminum components tailored to your specifications.